Achieving “Zero Waste”

Plasma arc technology offers a unique opportunity to achieve the “zero waste” goals by providing the capability to eliminate the need for land disposal of many hazardous wastes, and to recover energy from municipal solid wastes and other organic wastes, while producing salable byproducts and eliminating requirements for landfilling of ash or other residual materials.

What is PLASMA?

- “Fourth State” of matter

- Ionized gas at high temperature capable of conducting electrical current

- Lightning is an example from nature

Non-transferred arc plasma torch

In a plasma arc torch, the plasma gas serves as a resistive heating element to convert electricity into heat. Because it is a gas and cannot melt, temperatures in excess of 7000°C can be produced.

Characteristics of Plasma Arc Technology

- Plasma acts as a resistive heating element that cannot melt and fail

- Produces temperatures of 4,000°C to over 7,000°C

- Torch power levels from 100kW to 200 MW produce high energy densities (up to 100 MW/m3)

- Torch operates with most gases – not a combustion process

- Elimination of requirement for combustion air

- Reduces gas volume requiring treatment

- Reduces potential for formation of complex organics (i.e., dioxins and furans)

Plasma torch in operation

Plasma arc technology is ideally suited for waste treatment

- Hazardous & toxic compounds broken down to elemental constituents by high temperatures

- Organic materials

– Pyrolyzed or volatilize

– May be converted to fuel gases

– Amenable to conventional off-gas treatment

- Residual materials (radionuclides, heavy metals, etc.) immobilized in a rock-like vitrified mass which is highly resistant to leaching

Plasma arc technology remediation experience

- Heavy metals

- Radioactive wastes

- Industrial sludges

- Municipal solid waste

- Electric arc furnace dust

- Liquid/solid organic wastes

- PCB’s

- Asbestos

- Chemical wastes

- Medical wastes

- Plastics

- Used tires

Waste Processing Applications of Plasma Arc Technology

Waste Destruction Applications

- Melting and vitrification of inorganic materials

- Pyrolysis of organic materials

– Molten metal or glass bath provides heat transfer

– Heat causes breakdown of complex materials into elemental components

– Rapid quenching prevents complex compound formation (dioxins and furans)

– Water gas shift reaction to remove carbon

* C + H2O -> H2 + CO

– Gaseous products are fuel and simple acid gases

– Vitreous residue is resistant to leaching – suitable for aggregate

U.S. asbestos stockpile disposal

French Asbestos-Containing Materials (ACM) disposal system

Incinerator ash disposal

Navy shipboard system

Recent Commercial Applications

- Mixed waste treatment facility-Richland, WA

– Allied Technology Group (ATG)

- Medical waste vitrification facility-Honolulu, HI

– Asia Pacific Environmental Technologies (APET)

- Incinerator ash vitrification facilities – Europe and Japan

– Europlasma

– IHI Inc./Westinghouse Plasma

Recent DoD Plasma Furnace Applications

- Plasma Arc Shipboard Waste Destruction System (PAWDS)

– U.S. Navy Warships (NSWCCD)

- Plasma Arc Hazardous Waste Treatment System (PAHWTS)

– U.S. Naval Base, Norfolk, VA (Office of Naval Research, Environmentally Sound ShipsProgram)

- Plasma Ordnance Demilitarization System (PODS)

– Naval Surface Warfare Center, Crane, IN (Defense Ammunition Center)

- Plasma Waste Treatment System (Pyrotechnics and Energetics)

– Hawthorne Army Ammunition Plant, NV (Armament Research and Development Engineering Center)

- Plasma Energy Pyrolysis System (PEPS) Demonstration Facility (Medical Waste and Blast Media), Lorton, VA

– U.S. Army Construction Engineering Research Laboratories (CERL)

- Mobile PEPS Demonstration System, U. S. Army CERL

Mobile Plasma Energy Pyrolysis System (PEPS)

GTRI Plasma Waste Processing & Demonstration System

- Developed by USACERL

- Congressional funding

- Capacity 10 tons/day

- Complete system

– Feed & Tapping

– Furnace

– Emissions control

– Wastewater treatment

– 1MW mobile generator

Plasma Waste Processing and Demonstration System

Plasma Processing for Energy and Materials Recovery

Plasma Processing for Energy and Materials Recovery

- Research on waste destruction noted that pyrolysis produced useful fuel gases and inert residuals from organic wastes including MSW

- Use of gasification technology has made plasma a more economically attractive alternative

Plasma Pyrolysis of MSW

Hitachi Metals Plasma MSW System – Japan

Hitachi Metals 200 TPD MSW Plant – Utashinai Japan

Hitachi Metals Utashinai, Japan Plant

Commercial 200 ton/day plasma processing system

- Designed for Municipal Solid Waste (MSW) and Automobile Shredder Residue (ASR)

– Represents MSW from approximately 30,000 US households

- Plant has two plasma reactors

– Four 300 kW torches (Westinghouse Plasma Corp.) per reactor

– Each reactor will process ~4 tons/hr

- Generates 7.9 MW of electricity (4.3 MW to grid)

– Could supply 4,000 US households with electricity (up to 15% of households supplying waste to the system)

- Fully operational in April 2003

Quantum Signing Ceremony for Plasma Gasification Consideration in China

Plasma Gasification: MSW Waste-To-Energy U.S. Projects Under Development

- St. Lucie County, FL: 3,000 TPD

- Tallahassee, FL: 1,000 TPD

- New Orleans, LA: 2,500 TPD

- International Falls, MN: 150 TPD

- Sacramento, CA: 1,000 TPD

- State of Hawaii, Location: TBD: 300 TPD

Quantum Plasma Gasification MSW Waste-To-Energy Projects Under Discussion and Development

- City of Manila, P.I. – 5,000 TPD in 500 TPD Units.

- Cebu City, P.I. – 3,500 TPD in 500 TPD Units.

- Clark Field, P.I. – 4,000 TPD in 500 TPD Units.

- Perth, Australia – 4,000 TPD in 500 TPD Units.

- Mexico City, Mexico – 5,000 TPD in 500 TPD Units.

- Sydney, Australia – 1,000 TPD in 500 TPD Units.

US Plasma Gasification MSW Waste-To-Energy Projects Currently Under Negotiation by Quantum

- Houston, Texas — 2,000 TPD in 500 TPD Units.

- San Bernardino, CA –2,000 TPD in 500 TPD Units.

- Chino, CA — 2,000 TPD in 500 TPD Units.

- Elgin, Oregon — 2,000 TPD. in 500 TPD Units.

- Seattle, Washington — 2,000 TPD in 500 TPD Units.

- Honolulu, Hawaii — 2,000 TPD in 500 TPD Units.

- Phoenix and Tucson, AZ — 2,000 TPD in 500 TPD Units.

- Albany, NY — 2,000 TPD in 500 TPD Units.

- Rensaleer, NY — 2,000 TPD in 500 TPD Units.

Vitrified MSW residue

Estimated Production of Profitable Bi-Products per ton (metric) of material sent to the Plasma Reactor

- Glass rock-400 lbs

- Electricity- 800 kilowatt hours to 1 megawatt

- Steam…available for electricity, amount varies with design

- Syngas…available, amounts varies with design

- Distilled water…can be included in most plants

- Petroleum bi-products…varies with design.

Leachability of Vitrified MSW Residue (TCLP)

MSW Solid Byproduct Uses

PLASMA PROCESSING OF MSW AT COAL-FIRED POWER PLANTS

Concept

- Collocate MSW plasma processing plants (in modules of 1,000 TPD) with existing operational coal-fired power plants.

- The amount of coal supplied to a plant will be reduced, proportionate to the thermal output of the MSW plant.

- The hot gaseous emissions from the plasma plant afterburner system will be fed directly into the coal plant combustion chamber to supplement the combusted coal gases.

- The combined plasma and coal gaseous emissions would produce steam and power equal to the normal coal plant generating capacity.

- MSW would replace large volumes of coal for power generation in a very efficient, cost-effective and environmentally cleaner operation.

PLASMA PROCESSING OF MSW AT COAL-FIRED POWER PLANTS

Reduced Capital Costs of MSW Plant

- Use existing power plant facilities

– Steam generation system

– Off gas treatment system

– Electrical generating system

- Use existing transportation network

- Build on power plant land, if feasible

PLASMA PROCESSING OF MSW AT COAL-FIRED POWER PLANTS

Summary

By 2020, if all MSW was processed by plasma at coal-fired power plants (1 million TPD), MSW could:

- Supply about 5% of U.S. electricity needs

- Replace about 140 million TPY of coal

- Eliminate about 15 million TPY of coal ash going to landfills

- Provide significantly cleaner coal plant air emissions

- Support the goals of the Clear Skies Act

Quantum’s Mobile Plasma Units

- Quantum is one of the few international companies capable of producing and operating mobile plasma units designed to directly address hazardous waste sites.

Picture of an On-Site Remediation Plant to be manufactured into a Quantum Plasma Vitrification Facility and adaptable for Synthetic Gas Recovery and electrical generation.

2009 Auto-Cad Design of a “3000 Ton Capacity” Plasma Gasification Facility Designed by Our Build Engineer

Advanced Plasma Research

Quantum, in coordination with leading US universities, is heavily involved in the development and production of advanced Mobile Plasma Treatment Systems which are designed to address the destruction of small, energetic ordnance devices and waste mixtures, such as soil contaminated with organic compounds. These new systems have full recapture, and are 99.9% Green.

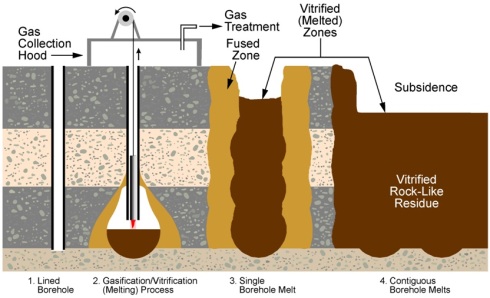

Sequence for in-situ Plasma Gasification Applications

Landfill remediation concept

PLASMA: THE TREND OF THE FUTURE. PROJECTED RENEWABLE ENERGY SOURCES FOR THE YEAR 2020.

Capital Costs: Incineration vs. Plasma Gasification Facilities

Potential DoD Applications

- Processing of hazardous wastes

– Major installations

– Industrial activities (depots, Air Force Plants)

- “Bare Base” and “Zero Footprint” Operations

– Process solid and sanitary wastes

– Eliminate landfills or shipping of residuals

– Recovery of energy as steam or hot water

Quantum Goals for the international implementation of our Plasma Arc Technology

- Construction of “Model” Quantum Plasma sites in the U.S., and key countries such as China, the Philippines, and Australia.

- Securing U.S. and foreign regulatory acceptance and permitting.

- Media programming, geared to inform the public of the potential of Plasma.